Abrasive Blasting Media Properties

When it comes to Abrasive Blasting Media the following will impact the size and shape of your Depth Profile. The Abrasive Media Shape, Size, Hardness, Velocity, and Density all affect your Depth Profile and finished product. The idea is to estimate the depth profile as close as you can with the media properties and then adjust, the only field adjustable variable possible, velocity.

Abrasive Media Shapes

There are 4 main shapes to Abrasive Blasting Media. The underlying substrate and surface contaminate will be impacted differently by these different shapes.

Angular shaped abrasive media will cut through rust and other soft surface contaminates quickly and easily. This will also create deep and sharp Depth Profiles on your cleaned surface like Mild steel. This shape has a high productivity rate on soft surface contaminants and rust. Angular shaped abrasive media will cut through rust and other soft surface contaminates quickly and easily. This will also create deep and sharp Depth Profiles on your cleaned surface like Mild steel. This shape has a high productivity rate on soft surface contaminants and rust. |

|

Sub-Angular shaped abrasive media does a good job cutting through rust and other soft surface contaminates almost as well as Angular. The Depth profile will be a little less deep on mild steel but will still give you an adequate anchor pattern. Sub-Angular shaped abrasive media does a good job cutting through rust and other soft surface contaminates almost as well as Angular. The Depth profile will be a little less deep on mild steel but will still give you an adequate anchor pattern. |

|

As you move closer to the rounded shaped abrasive media, you reduce the size of the depth profile and its abrupt peaks. The Sub-Rounded Media is good for harder surface contaminates like mill scale and other brittle contaminates. Depth profile will be reduced as well. As you move closer to the rounded shaped abrasive media, you reduce the size of the depth profile and its abrupt peaks. The Sub-Rounded Media is good for harder surface contaminates like mill scale and other brittle contaminates. Depth profile will be reduced as well. |

|

Rounded shaped abrasive media does an excellent job creating a surface like the shot peened surface. The Depth Profiles are minimal and the hard surface contaminants are removed with ease. Rounded shaped abrasive media does an excellent job creating a surface like the shot peened surface. The Depth Profiles are minimal and the hard surface contaminants are removed with ease. |

Abrasive Media Size

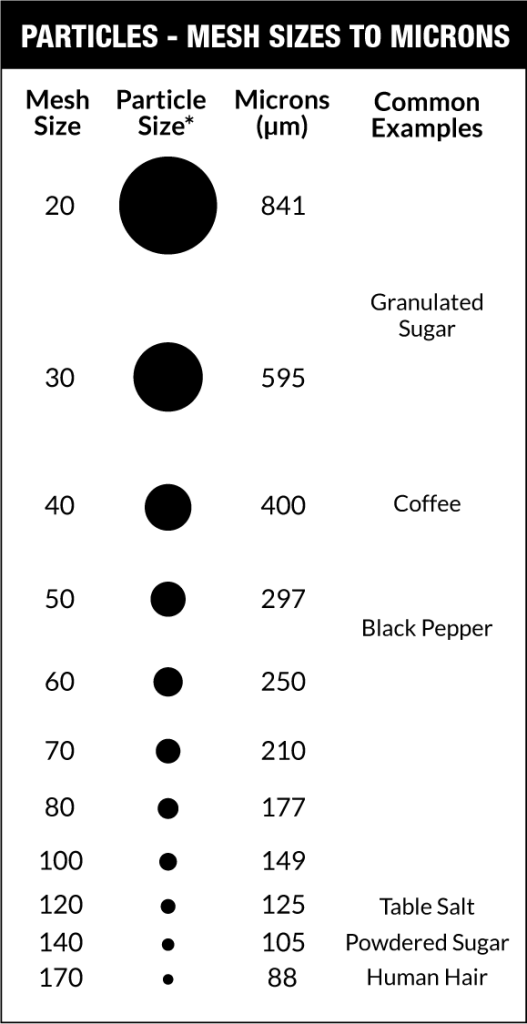

Now that you understand how the shape will impact the final product, Let’s discuss size and how it impacts the surface. Size, of course, will increase the diameter of your Depth Profile but will also give you fewer particles per cubic foot of air. Smaller Particles do a better job at cleaning but if you’re worried about the Anchor Pattern your coating will attach to, use the size that will give you your desired finish. Again, there are other properties, like shape, that will help you achieve this final depth profile. Use the smallest particle necessary to achieve the depth profile you desire.

Abrasive Media Hardness

Softer Abrasive Media, like plastic abrasives or natural media (walnut shells or corn cob), do a fantastic job at removing paint or other surface contaminants. They also do a fantastic job at not damaging the softer surfaces you are preparing. If you are wanting a specific anchor pattern or depth profile on a harder surface, you need to look at abrasive media that is higher on the Mohs Hardness Scale. This depends on the Mohs Hardness of the surface you are preparing.

Harder Abrasive Media will create a deeper depth profile due to the impact of the hard abrasive on an equally hard or harder surface.

Abrasive Media Density

The Density of your Abrasive Media controls a couple of different variables in Blasting. One variable is kinetic energy, when all other variables are equal, specifically velocity, the higher density abrasives carry more kinetic energy. This will increase the depth profile that the abrasive will create on your surface. The higher Density abrasives usually create less dust. The lower density abrasives are generally used for cleaning and deburring. Density is measured by Specific Gravity (g/mL) Grams per Milliliter or (g/cm3) Grams per Centimeter cubed. You will often see it shown as 1.0 SG, that is the specific gravity of water.

Common types of Abrasive Media

|

Silica Sand The Original Abrasive Blasting Media which caused a serious health hazard in the industry called Silicosis. This Abrasive Blasting Media is no longer recommended due to the Health issues it will cause. Mesh sizes: 6-270 | Hardness: 5-6 MOHS | Density: 2.65 SG | Shape: Rounded | Cost: $ Silica Sand The Original Abrasive Blasting Media which caused a serious health hazard in the industry called Silicosis. This Abrasive Blasting Media is no longer recommended due to the Health issues it will cause. Mesh sizes: 6-270 | Hardness: 5-6 MOHS | Density: 2.65 SG | Shape: Rounded | Cost: $ |

|

|

|

|

|

|

|

|

|

|

|

|

Glass Beads Glass Beads are used for a variety of cleaning and peening cosmetic finishes. You will see this used to clean off calcium deposits and clean up aircraft propellers, and it also does great on other delicate surfaces. The cost is high but the Hardness (5.5 Mohs) and the Density (2.5 SG) make it a good choice. Glass Beads Glass Beads are used for a variety of cleaning and peening cosmetic finishes. You will see this used to clean off calcium deposits and clean up aircraft propellers, and it also does great on other delicate surfaces. The cost is high but the Hardness (5.5 Mohs) and the Density (2.5 SG) make it a good choice. |

|

|

Glass Beads: Glass is not as aggressive a blasting media as other materials, such as steel shot or silicon carbide. However, it is an excellent choice for applications that require a softer, brighter finish. It is well suited for stainless steel applications. Glass beads can also be recycled multiple times. Glass Beads Blasting Media – Creating a softer, brighter finish than angular abrasives, Glass Beads offer a silica-free option for shot blasting, peening, honing, cleaning and light deburring. Mesh sizes: 30-325 | Hardness: 5.5-6 MOHS | Density: 2.5 SG | Shape: Rounded | Cost: $

|

|

Plastics Plastics are soft and are usually considered a safe alternative to chemical stripping on delicate surfaces. The density is low so it will not damage the surface like heavier abrasive media. The plastics are expensive but a viable option. Plastics Plastics are soft and are usually considered a safe alternative to chemical stripping on delicate surfaces. The density is low so it will not damage the surface like heavier abrasive media. The plastics are expensive but a viable option. |

|

|

Plastics: Plastic abrasive is a dry thermoset cleaning media made from crushed urea, polyester or acrylic. Each varying and available in a range of hardness and particle size. Plastic is generally regarded as the best media for mold cleaning, blasting of plastic parts, or in applications where the removal of the substrate material is not permitted. Common industries include automotive, aviation, boating, electronics and industrial applications. Plastic Blasting Media– Urea is the most heavily used plastic abrasive. Available in a variety of sizes, urea is ideal for applications such as auto restoration to deliver an efficient stripping rate without damage or warping of the substrate. Mesh sizes: 12-80 | Hardness: 3-4 MOHS | Density: 1.5 SG | Shape: Angular | Cost: $

|

|

Walnut Shells You can’t get much more Eco-Friendly than Walnut shells, but you’ll pay extra for it. Walnut is another great option for cleaning those delicate surfaces. Being soft and its density make it a great option for cleaning up those precious surfaces Corn Cob is another Eco-Friendly Abrasive being used today. Walnut Shells You can’t get much more Eco-Friendly than Walnut shells, but you’ll pay extra for it. Walnut is another great option for cleaning those delicate surfaces. Being soft and its density make it a great option for cleaning up those precious surfaces Corn Cob is another Eco-Friendly Abrasive being used today. |

Walnut Shells: Walnut shell abrasive is a hard naturally occurring material made from crushed walnut shells. It is the harder of the soft abrasives, available in a variety of sizes for blast cleaning and polishing softer surfaces that could incur damage from harsher abrasives. Useful for cleaning auto body panels, electric motors and aircraft engines, dies and molds, polishing of soft metals, fiberglass, wood, plastic and restoring antique surfaces.

It can also be used in tumbling operations for polishing gems and jewelry., polishing watches and jewelry

- Walnut Shells Blasting Media – is the most versatile of the organic media due to its angular, durable shape yet is still considered a soft media. Use as an economical, biodegradable alternative for sensitive blasting operations that require aggressive stripping without effect on the substrate.

Mesh sizes: 6-100 | Hardness: 3-4 MOHS | Density: 1.2-1.35 SG | Shape: Subangular | Cost: $

Baking Soda

Sodium Bicarbonate abrasive is an environmentally friendly crystallized version of baking soda. It is excellent for stripping paint off vehicles, boats or other restoration projects. Will not damage glass, chrome or rubber and can be used for all general cleaning jobs. Ideal for cleaning an engine compartment or other equipment. Soda will not pit, or warp metal surfaces and offers easy cleanup by just washing away with water.

Baking Soda Media: around plant life and grass can be an issue. One biological process that can be disturbed by the presence of any free sodium ion, including sodium bicarbonate is the process of photosynthesis. This process uses light in the presence of chlorophyll and water to convert carbon dioxide to sugars, the plant life nutrient. Depending on the type of plant, sodium bicarbonate can produce temporary discoloration or cause more serious damage.

Mesh sizes: 55-170| Hardness: 2.5 MOHS | Density: 2.2 SG | Shape: Subangular | Cost: $ | PH: 8.2

GARNET Garnet is a gemstone with excellent naturally abrasive properties. This hard abrasive is fast-cutting, low-dust producing and low-consuming, excellent for removing tough coatings, paint, rust and mill scale from steel. Garnet also permits precise feathering control. A good general outdoor surface preparation abrasive. Mesh sizes: 30-120 | Hardness: 7-7.5 MOHS | Density: 3.5-4.3 SG | Shape: Subangular | Cost: $ DEPTH PROFILES FOR GARNET (for steel) Mesh Size Max Profile Recommended Usage 30/60 2.4 – 4.7 mil Steel, Concrete, Asphalt, Aluminum 80 1.5 – 3.6 mil Steel, Concrete, Asphalt, Aluminum 120 0.5 – 2.0 Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint 150 0.5 – 1.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint

GARNET Garnet is a gemstone with excellent naturally abrasive properties. This hard abrasive is fast-cutting, low-dust producing and low-consuming, excellent for removing tough coatings, paint, rust and mill scale from steel. Garnet also permits precise feathering control. A good general outdoor surface preparation abrasive. Mesh sizes: 30-120 | Hardness: 7-7.5 MOHS | Density: 3.5-4.3 SG | Shape: Subangular | Cost: $ DEPTH PROFILES FOR GARNET (for steel) Mesh Size Max Profile Recommended Usage 30/60 2.4 – 4.7 mil Steel, Concrete, Asphalt, Aluminum 80 1.5 – 3.6 mil Steel, Concrete, Asphalt, Aluminum 120 0.5 – 2.0 Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint 150 0.5 – 1.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint  Crushed Glass Crushed Glass Grit is a silica-free consumable abrasive that offers aggressive surface profiling and removal of a variety of coatings. Manufactured from 100% recycled bottle glass, Crushed Glass Grit produces a whiter, cleaner finish relative to mineral/slag abrasives. Crushed glass is the abrasive of choice for preparing concrete. Mesh sizes: 30-400 | Hardness: 5.5-7 MOHS | Density: 2.5 SG | Shape: Angular | Cost: $ DEPTH PROFILES FOR CRUSHED GLASS (for steel) Mesh Size Max Profile Recommended Usage 20/30 2.5 – 4.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick 30/70 2.0 – 3.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint 50/100 0.5 – 2.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint

Crushed Glass Crushed Glass Grit is a silica-free consumable abrasive that offers aggressive surface profiling and removal of a variety of coatings. Manufactured from 100% recycled bottle glass, Crushed Glass Grit produces a whiter, cleaner finish relative to mineral/slag abrasives. Crushed glass is the abrasive of choice for preparing concrete. Mesh sizes: 30-400 | Hardness: 5.5-7 MOHS | Density: 2.5 SG | Shape: Angular | Cost: $ DEPTH PROFILES FOR CRUSHED GLASS (for steel) Mesh Size Max Profile Recommended Usage 20/30 2.5 – 4.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick 30/70 2.0 – 3.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint 50/100 0.5 – 2.5 mil Steel, Concrete, Asphalt, Aluminum, Fiberglass, Brick, Boat Bottom Paint MINERAL SANDS Mineral sands, like olivine and staurolite, are fast-cutting, low dust abrasives that contain less than 5% silica per volume. Good for removal of rust, paint, weathered coatings and mill scale. More expensive than Crushed Glass, but still affordable. Mesh sizes: 20-120 | Hardness: 6.5-7.5 MOHS | Density: 3.3-3.6 SG | Shape: Angular to subangular (olivine), subangular to rounded (staurolite) | Cost: $

MINERAL SANDS Mineral sands, like olivine and staurolite, are fast-cutting, low dust abrasives that contain less than 5% silica per volume. Good for removal of rust, paint, weathered coatings and mill scale. More expensive than Crushed Glass, but still affordable. Mesh sizes: 20-120 | Hardness: 6.5-7.5 MOHS | Density: 3.3-3.6 SG | Shape: Angular to subangular (olivine), subangular to rounded (staurolite) | Cost: $ COAL SLAG Coal slag is by-product of coal-burning power plants, considered a “green” abrasive because it would otherwise be disposed of as waste. It is a relatively cheap, low dusting abrasive with low free silica, but is considered a dirty abrasive and not widely used in wet abrasive blasting because the high number of “fines” (fine particles) mud up on the surface. Typical applications include the removal of rust, paint, weathered coatings and scale from steel and concrete. Many states are starting to ban the use of coal slag. Mesh sizes: 12-80 | Hardness: 6-7.5 MOHS | Density: 2.7 SG | Shape: Angular | Cost: $

COAL SLAG Coal slag is by-product of coal-burning power plants, considered a “green” abrasive because it would otherwise be disposed of as waste. It is a relatively cheap, low dusting abrasive with low free silica, but is considered a dirty abrasive and not widely used in wet abrasive blasting because the high number of “fines” (fine particles) mud up on the surface. Typical applications include the removal of rust, paint, weathered coatings and scale from steel and concrete. Many states are starting to ban the use of coal slag. Mesh sizes: 12-80 | Hardness: 6-7.5 MOHS | Density: 2.7 SG | Shape: Angular | Cost: $